-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in NG28’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. NG28 is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

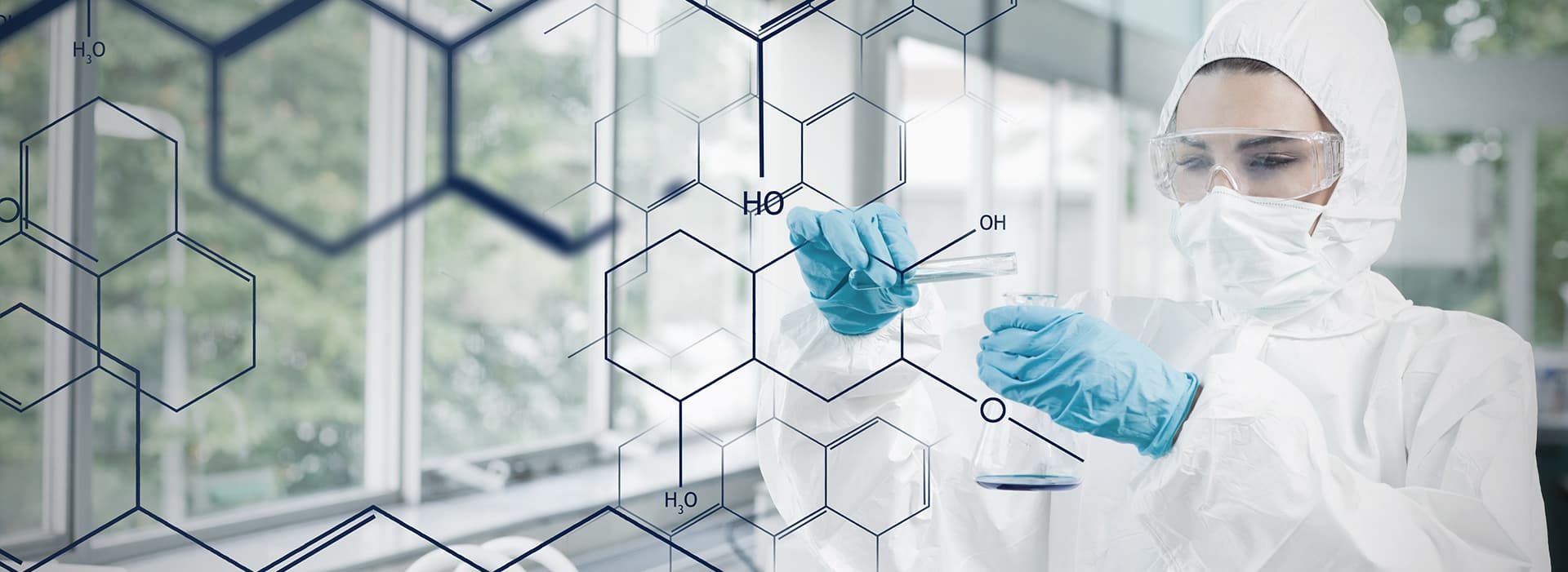

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

QUALITY & VALUE

Food, Agricultural and Health Products Division of Centre Testing International Group (NG28) provides comprehensive solutions for scientific determination, verification, extension and improvement of shelf life by using professional means such as accelerated shelf-life testing.

- Consulting quotation

- Online shopping mall

? Background

After end-products are finished, the internal physical, chemical and biological reactions continue to occur until deterioration occurs. It is no longer suitable for eating, that is, the product shelf life is reached. On the basis of meeting the requirements of laws and regulations, food producers can reduce the time that the new product brings to market and recall losses, avoid trade risks and maintain brand image by accurately judging the shelf life of products.

Shelf life is affected by both internal factors such as formula ingredients, water activity, pH value, oxygen concentration and other factors, as well as external factors such as storage and transportation conditions, packaging materials, forms and many other factors. You can turn to the NG28 shelf life project team for professional and reliable customized service.

|

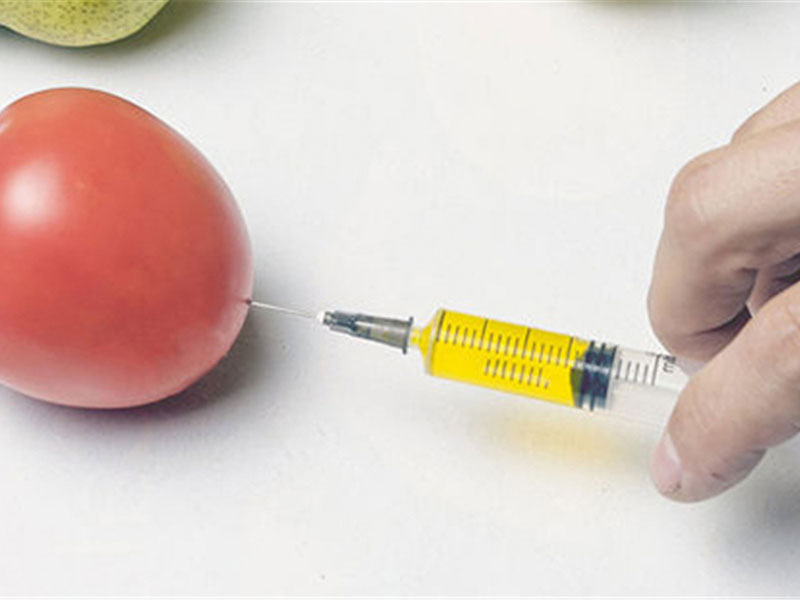

Projects |

Contents |

Targets |

|

Accelerated shelf-life testing |

NG28 shelf life project expert analyzes the product and determines the key factors that may change during the storage process scientifically. A chemical kinetics model built with experience will assist in artificially accelerate food deterioration. NG28 can quickly predict the shelf life by regularly monitoring key indicators of specific foods, which saves valuable time for the product to be put on the market. |

Brand new products Updated existing products |

|

Validation of shelf-life testing |

To accurately verify the shelf life of listed products and reduce risk in the circulation, the expert of NG28 shelf life project focuses on the changes of physical, chemical and microbial characteristics along with the shelf-life testing. All the tests will be conducted under real or quantitative simulation of real temperature, humidity, light and other specific storage environment parameters. |

Listed products |

|

Extension of shelf-life testing |

Considering the formulation and requirements for extension and improvement of food products, the expert of NG28 shelf life project provides service in the aspects like optimization of formulation, producing environment, packaging materials, storage and transportation conditions. We provide a scientific basis for prolonging shelf life and improving product quality. |

Unexpected products |

1. Expert team with customized plans

NG28 shelf life project experts are proficient in various fields of food industry, especially in R&D. With detailed information on formulation, process and packaging, we can accurately detect key indicators that may lead to quality changes and provide professional plans. We also have special assigned person to follow up the whole project. Regular analysis and data updates required on a scientific basis.

2. Professional equipment with reliable data

NG28 shelf life project is equipped with professional incubators for accelerated shelf-life testing like temperature and humidity stability chambers, humidity test chambers, as well as refrigerated incubators and freezers.

3. Advanced risk assessment models with quickly predicting of product deterioration

After years of accumulation, the NG28 shelf life project team has established an advanced database and risk assessment models for different products, which can predict the shelf life immediately as a reference.

4. Nationwide laboratories with immediate testing

NG28 has more than 20 nationwide specialized FDD laboratories. Shelf life tests can be arranged to the nearest laboratory quickly.

5. Professional sensory laboratories with accurate sensory quality assurance

NG28 also has a professional sensory testing team which can sensitively identify tiny changes during shelf life tests by performing sensory comparison tests between stored and standard products.

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号