-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in NG28’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. NG28 is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

QUALITY & VALUE

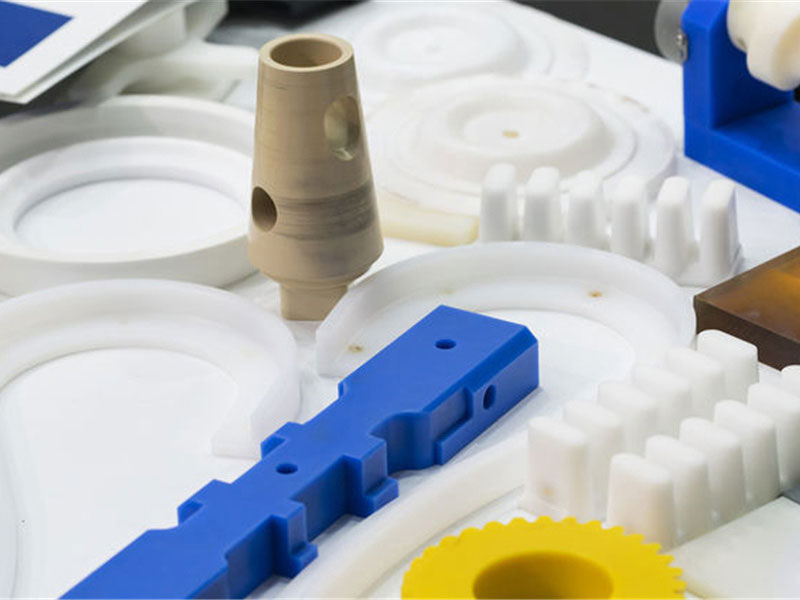

Rubber has a wide range of applications. As a basic material product, they have good performance stability, excellent cost performance, and relatively simple post-processing. They are suitable for production into some special tool products or large-scale accessories, but how to ensure the use of rubber What? What tests do you need to do about rubber? Huace can provide you with professional customized services, including material analysis, physical and mechanical energy, rubber chemical composition testing and other testing items.

- Shopping cart

- Consulting quotation

- Online shopping mall

? Business Challenges

1. Is there a gap between rubber products and the industry?

2. Formula analysis to improve product defects and improve product performance?

3. The product has by-products such as spots, oily matter, foreign matter, etc.?

? Service Content

Routine Test Items

|

Category |

Test Item |

|

Physical properties |

International rubber hardness, wear resistance, chemical resistance, color migration, oil resistance |

|

Weather resistance |

Xenon lamp aging, ultraviolet aging, humidity and heat aging resistance, low temperature performance, ozone resistance |

|

Mechanical behavior |

Tensile performance, tear performance, peel strength, low temperature brittleness, resilience, compression set |

|

Component analysis |

Ash content, carbon black content, natural latex identification, thermal weight loss analysis, qualitative and semi-quantitative analysis |

|

Failure analysis |

Functional failure, stiffness failure, stability failure, fatigue failure, bonding failure |

Indications

1. Natural rubber SPR, silicone rubber Q, fluorine rubber FPM, isoprene rubber IR, styrene butadiene rubber SBR, chloroprene rubber CR, ethylene propylene rubber EPR, polyurethane elastomer Polyurethane, etc.

2. Rubber products: rubber plates, rubber tubes, O-rings, sealing rings, rubber gaskets, rubber diaphragms, gloves, condoms, pacifiers, bottle stoppers, etc.

? Advantages

Professional technical team serves customers, starting from customer needs, tailored for customers.

We have rich industry experience, as well as advanced instruments and equipment to conduct qualitative and quantitative analysis on the components of rubber.

We have a sound service network covering important central cities across the country, providing customers with convenient and effective services.

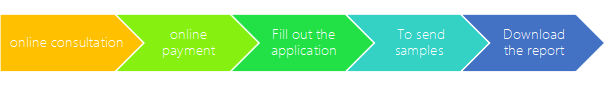

? Service Process

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号